A mechanical seal requires frequent repair and replacement. It is a costly thing. Therefore, it is important to follow some principles to choose the best seal flush plan for the single mechanical seal.

It allows the seal to operate in an environment that ensures optimal seal life without increasing cost from dilution of product or use of water.

This blog brings different flush piping plans and how to choose the right one among them.

#1 No flush plan

You can choose no flush plan in the following conditions:

- When the pump fluid is clean

- The fluid maintains temperature within the maximum and minimum limits of the seal

- The fluid is compatible with the components of the seal

- When there is no risk of solidifying or vaporizing of the fluid due to the friction heat

If this plan is used, then the chamber must be either tapered or self-venting.

#2 Bypass flush plan

If you want to choose the Bypass flush plan, then make sure these conditions are fulfilled:

- The fluid is compatible with the components of the seal

- The fluid contains solid that can put an adverse effect on the seal

- The temperature of the pumped fluid goes beyond the maximum temperature of the seal

In this method, piping runs from the point of pump discharge to the point where the flush connects to the seal gland. Thus, the fluid gets a flow, it passes through the seal and goes back into the pump via the chamber throat of the seal.

Alternatively, the fluid can be directed back to the pump section from the flush connection on the seal gland. It results in an opposite flow. The operating pressure at the seal drops by this method.

To make the process easy, sometimes, heat exchanger or pressure reducing orifice are installed along in the piping.

In the bypass flush method, the heat generated by the seal flows past the seal face. Hence, the operating temperature gets stabilized at the temperature of the fluid that is being pumped.

The bypass flush method is reliable and simple. It is cost-effective as well. There is no dilution of the product in this method.

It is a preferred method.

#3 External flush

It is useful when you want the isolation of the seal from the fluid. Here, water is injected into the seal gland flush with pressure. Water flows past the seal and mixes with the fluid. TO control the flush water flow, lip seal or restriction bushing is used. To measure the flow, flow meter, gauge, and control valves are used.

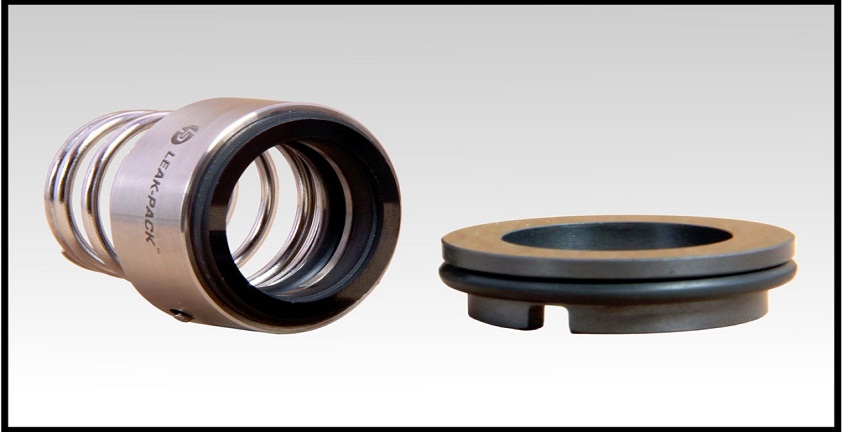

Leak-Pack is ISO 9001:2008 certified company and leading mechanical seals manufacturer & supplier in India, providing solutions to all types of leakages by manufacturing Mechanical Seals and Sealing Components as per customer’s drawings, samples or requirements. To know more about Mechanical Seal call on +91-(2739) 271592 or email at info@leakpack.com.

Also Read:

Why Use Mechanical Seals? Instead of Packing