If you see various types of mechanical seals, then you get several designs. Why do these designs differ? Because they are dependent on several factors like:

- Location of springs

- Choice of secondary seals

- Application type

- Cost

- Ease of installation

- Capability of sealing

What makes a mechanical seal design ideal? Here are five key characteristics or features. Read the blog to understand them in detail.

-

Stationary design

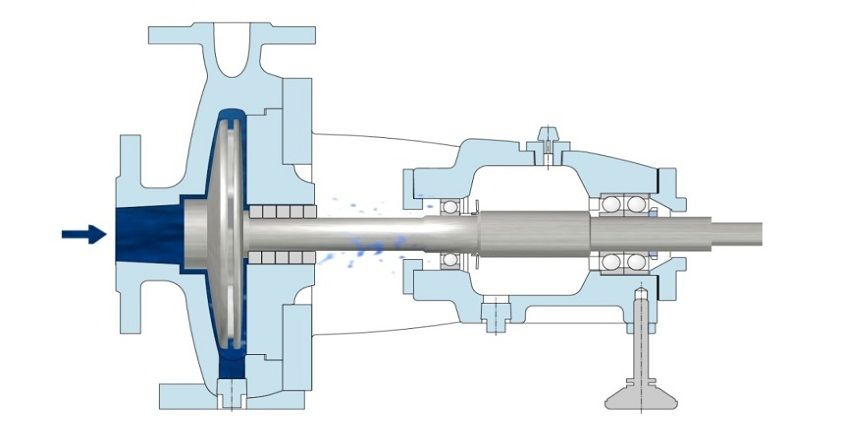

Every rotary mechanical seal has a spring mechanism in the rotating part. To make it efficient; the stuffing box face has to be perpendicular to the shaft.

When there is a misalignment, even if it is slight misalignment, the adjustment becomes difficult when the seals rotate at high speeds.

In a stationary seal, the springs remain stationary. They don’t rotate with the shaft. Hence, there is no need for correction or adjustment with each rotation.

-

Monolithic seal face

It is possible to make a mechanical seal with either monolithic seal face or inserted seal face. The inserted face design is inappropriate because of various limitations it has.

In this design, there is a difference in the thermal expansion and coefficients between the face material and holder material.

Due to this difference, the net interference force changes between the two parts. They are exposed to heat because of face friction.

Hence, the deform in seal face is quite common if inserted seal face design is used.

Monolithic seal face overcomes all these limitations.

-

Protected springs

If the springs are immersed in the unclean fluid, they accumulate dirt. It impairs the spring’s ability to respond to movement. The seal faces do not remain closed.

Eventually, there is a permanent failure in the springs.

In a good design, the springs remain protected from the exposure to the fluid.

-

Balanced design

In a seal design, the compression force is created by:

- pressure from the springs in the seal

- pressure from the hydraulic

- pressure of the liquid

This force keeps the faces of the seal closed.

In a properly balanced seal design, the seal ring area is minimized. It reduces the net closing force and provides better lubrication.

You get good-quality seals with higher pressure ratings.

-

Non-fretting design

The secondary seal moves with the springs and keeps the seal face closed. Springs adjust with each rotation and minimize the misalignment.

The dynamic secondary seal moves back and forth with each revolution. It doesn’t let the protective layer to form. It causes erosion of the unprotected area.

The non-fretting design does not have this limitation.

Leak-Pack is ISO 9001:2008 certified company and one of the best mechanical seals suppliers in India, providing solutions to all types of leakages by manufacturing Mechanical Seals and Sealing Components as per customer’s drawings, samples or requirements. To know more about Mechanical Seal call on +91-(2739) 271592 or email at info@leakpack.com.

Also Read: