Every industry follows specific operating standards. For example, in a huge oil and gas refinery, there are detailed specs for every equipment and tool.

Whether it is a pump or turbine, or a mechanical seal, there are written procedures and details of everything. Even to decide about a seal, one has to follow the product specifications and preferences.

In a smaller industry, the procedures may not be that systematic and documented but they also follow operating protocols.

Facility managers and plant managers accept API Standard 682 as the industry benchmark to specify shaft sealing system for rotary as well as centrifugal pump. It is regardless of the size of the company.

The idea behind following the standard is that anyone who wants to install a seal can read the API 682 document and choose reliable and appropriate seal. The objective is to bring a uniformity in the process.

What are the six important factors that should be considered while choosing the mechanical seal for the first time? Here are they.

#1 Experience and knowledge of stakeholders

Seal manufacturers, end users and engineering companies are using their combined knowledge and experience while selecting and operating end-face mechanical seals. API 682 standard document helps in the selection process.

#2 Scope of API 682

Though the intention of launching API 682 was to assist petroleum, chemical and natural gas companies, it is refenced as a generic document in other industries also. To get the best advantage of it, one has to understand the scope of the standard well.

#3 Uses of illustrations

The standard document API 682 has figures and illustrations. They provide normative details in the form of tables and clauses to understand the difference between requirement and suggestions.

These illustrations and figures should be understood well.

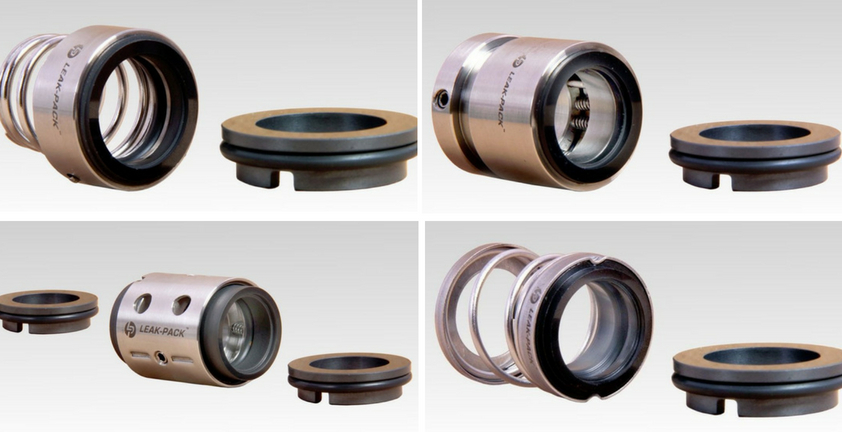

#4 Design of the mechanical seal

Seal is divided into three categories, three arrangements and three types in the API 682 standard document. It gives the flexibility of combining a seal’s component part into any configuration or orientation. There are advantages and disadvantages of every orientation. It should be evaluated on the parameters of system disturbance, performance and application.

#5 Defaults

Default means the predefined value of every parameter. Unless specifically defined, the default standards should be selected for the below parameters:

- Seal type

- Stationary or rotating seal

- Arrangement of the seal

- Orientation and configuration of the seal

- Material

- Bushing

#6 Accuracy

It is important to maintain high accuracy while picking a mechanical seal.

Leak-Pack is ISO 9001:2008 certified company and leading mechanical seals manufacturer & supplier in India, providing solutions to all types of leakages by manufacturing Mechanical Seals and Sealing Components as per customer’s drawings, samples or requirements. To know more about Mechanical Seal call on +91-(2739) 271592 or email at info@leakpack.com.

Also Read: