A rotary union is a device that provides a seal amid a stationary supply passage and a rotating part, thereby enabling fluid transfer. It has various names, primarily reliant on application and industry.

Irrespective, the fundamental objective of a rotary union stays the same, providing media from a still input to a specific rotating part.

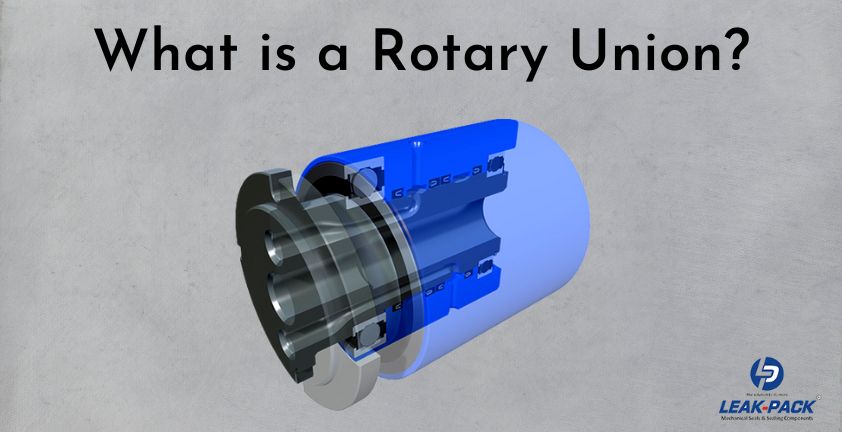

The Elements and Components of a Rotary Union

- Housing: This explicitly holds all the other elements of the rotary union. It possesses an inlet port to which the line supplying the fluid is linked.

- Shaft: This precisely transfers the medium through the involved device right into the rotating part.

- Bearings: These are applied to enable the shaft to rotate. They come as roller-style bearings or non-roller-type bearings.

- Seals: These are significant elements that are developed to avert the media from leaking externally to the rotary union while in process.

Where are Rotary Unions Utilized?

Rotary unions are applied across numerous marketplaces comprising industrial automation, food industry, alternative energy, defense, oil & gas, and aerospace. They are extensively used, and some of their applications include:

- Computerized Numerical Control (CNC) Machine Cooling

Coolant must be provided to diverse parts made of enduring metal machining. This fluid averts over-heating, sustains dimensional stability, and clears machined remains.

- Bottle Filling and Capping

Beverages are bottled and then capped by automated systems. Rotary unions are used to precisely feed the applicable fluid from a central supply into these beverage bottles as they pass along a conveyor.

- Hydro Dam Turbine Control

Hydroelectric dams integrate power as water flows along the turbine blades. Hydraulic lines are utilized to regulate the opening and closing of gates and the succeeding flow of water.

- Floating Production Storage and Offloading

Toroidal swivels are used in mooring systems for explicit offshore vessels which gather oil and gas from the reservoirs. These multifaceted systems run under tremendous flow rates while experiencing considerable mechanical stresses.

- Liquefied Natural Gas (LNG) Loading Arms

Loading arms are utilized to transfer fluid cargo to and from tanker trucks, offshore vessels, and railway vehicles. They need to continuously deliver cargo without leaks through precise sealing.

Key Takeaways

Seal designs for rotary unions must be sensibly comprehended. Materials must be sensibly chosen, with finishes and well-machined, and get fits cautiously.

Because of the dynamic nature of these devices, sealing is essential to ensure suitable transfer of media while capitalizing on the life of the rotary union.

Leak-Pack is ISO 9001:2008 certified company and one of the best mechanical seals manufacturers, exporters and suppliers in India, providing solutions to all types of leakages by manufacturing Mechanical Seals and Sealing Components as per customer’s drawings, samples or requirements. To know more about Mechanical Seal call on +91-(2739) 271592 or email at info@leakpack.com.

Also Read: