Know the parts of mechanical seal

In case of pumps and other mechanical devices, it is a critical thing to keep the large volumes of pressurized fluid to keep inside when the rotating shaft enters the wet area of the pump.

A mechanical seal does it effectively, and hence, considered very important.

All the mechanical seal parts have a smooth flawless performance and a long service life. Here you know about the different parts of mechanical seal.

Attempts have been made to eliminate the leakage, but practically there is a minimal leakage which is acceptable.

Several benefits make mechanical seals a preferred component in a mechanical environment.

Since the seals minimize the leakage, there is a safe work environment. No more wet and slippery floors, no more bearing failure because of leaking fluids and no more wear and tear of shaft sleeves.

Maintenance department gets a sigh of relief as there is no need of replacing the packing or adjusting the alignment again and again.

It is needless to say that the mechanical seals save money too.

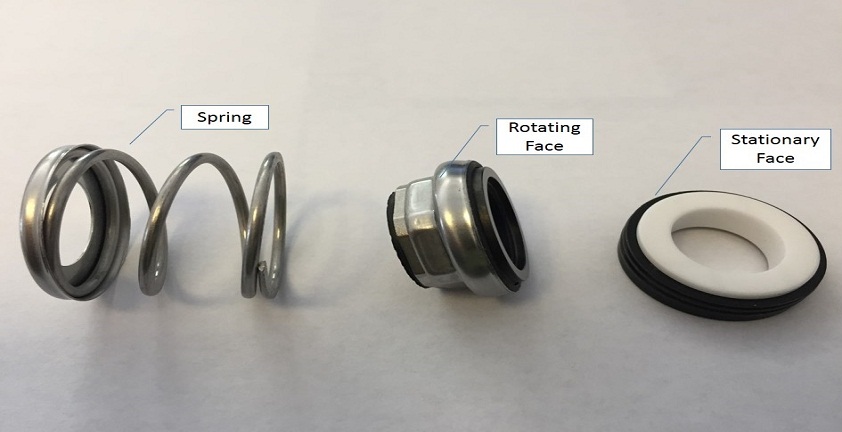

Understand the components of mechanical seals

You get a wide variety of mechanical seals in the industrial applications. They are available in different designs, but the mechanical seal face material is the most important aspect.

If we consider a mechanical end face ring, then the basic components are the seal rings, mating rings, secondary sealing elements, a means of actuation, and a means of drive. The seal ring and mating rings are called the primary sealing surfaces.

For engineered mechanical seals, the mechanical seal faces are machined to order. Manufacturers of mechanical seals stock a long array of shapes and sizes of seal rings and mechanical seals.

The primary sealing surfaces are the most important parts. Therefore, it is called the heart of the mechanical seal.

The secondary sealing elements are O-rings, PTFE wedges, and rubber diaphragms.

The sealing surfaces have the combination of hard and soft material. Usually, Silicon carbide, ceramic or tungsten carbide is preferred as hard material. The soft material is chosen based on the temperature, pressure and chemical properties of the liquid.

The two rings are in the intimate contact when one ring remains stationary, and the other one rotates with the shaft.

The lapping process is used to machine the rings so that the desired degree of flatness is obtained.

The rings and seals are available in both raw, and semi finished conditions. You get seal faces made from Tungsten Carbide, ceramic, carbon, and Nitrile, Silicon Carbide, etc.

Dissimilar materials (one hard and one soft) are used for the faces so that there is no adhesion of the faces. Carbon-graphite and ceramic are preferred material for making mechanical seal faces. In some cases where abrasive material is handled, both surfaces are hard.

Typically, a mechanical seal contains:

- Secondary static seals, V-rings, O-rings or wedges

- Static seal or stationary component

- Seal for the rotating component to the shaft.

- A spring member; metal bellows, multiple spring or single spring

- Other hardware such as gland rings, compression rings, collars, shaft sleeves, etc.

Mechanical seals are one of the important mechanical components used in different types of pumps and other devices.

Leak-Pack specialize in providing solutions to all types of leakages by manufacturing Mechanical Seals and Sealing Components as per customer’s drawings, samples or requirements. To know more about Mechanical Seal call on +91-(2739) 271592 or email at info@leakpack.com.

Read More Articles:

How does a mechanical seal function?