Know more about how mechanical seal work

Mechanical Seal – Mechanical engineering is a constantly evolving niche. Every year, there are new developments and advancements that make the processes simpler and better.

Gone are the days when the majority of the pump shafts used soft packing rings compressed by packing glands.

The mechanism was effective, but there was a good amount of leakage. It was to keep the packing lubricated and the temperature below the threshold.

As the technology advanced, new and advanced mechanical seals replaced the earlier technology. The results were much superior and effective than ever before.

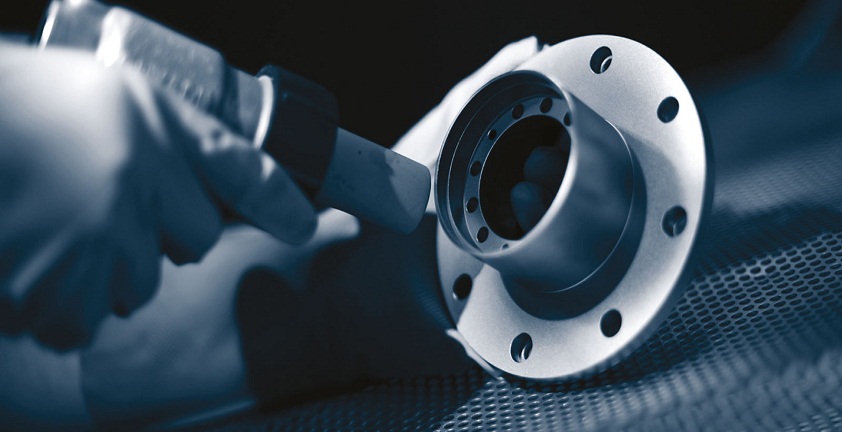

Components of a mechanical seal

It is not a very complex device. A typical mechanical seal consists of:

- Rotary seal face with a rotating mechanism to spin it at the same speed of the pump shaft

- Stationary seal face

- A gland or an integral stuffing box cover (for retaining the stationary face)

- Tension assembly to keep the rotary face in the place (it uses metal bellows or springs)

- Static sealing gaskets

- Elastomeric bellows

How is the job of leakage prevention accomplished by a mechanical seal?

- The mechanical seals prevent leakage around the shaft of the pump with two flat surfaces; one is stationary, and another is rotating.

- Today, the majority of the pumps use mechanical seals. If the application requirements are understood well, and the right type of seals are used; then they give an outstanding performance.

- The mechanical seals are widely used in pumps, mixers, and agitators in manufacturing and maintenance environment. The seals are designed to fulfill the exceeding demands of industries.

- They can withstand high temperatures and high RPM by using the combination of seal and seat face and secondary seals.

- In the mechanical seals, a small leakage is there across the faces. It forms a hydrodynamic film. However, the leakage is hardly noticeable, and it evaporates immediately.

Key benefits of using mechanical seals

- Since the mechanical seals offer superior performance, the leakage is almost invisible, and the power loss is minimal due to less friction; they are quite popularly used in different applications.

- Even if the one part remains still and the other rotates, there is no significant wear and tear of the shaft or sleeve.

- These seals offer a high level of flexibility and can accommodate the ‘end play’ and shaft deflections without any drop in the performance.

- There is no periodic maintenance needed, and it gives relentless, trouble-free service for a long time.

Selection of the seal type and arrangement depends on the desired reliability levels, emission standards and life cycle costs for the pump application. Single or double seals are the preferred types.

When the seal faces are properly polished and flat, and they are installed perpendicular to the shaft, and the force of the spring is just sufficient to maintain contact of the faces; mechanical seals generate the optimal performance.

Life of mechanical seals depends on many factors such as usage, wear and tear, operating environment and so on.

Leak-Pack specialize in providing solutions to all types of leakages by manufacturing Mechanical Seals and Sealing Components as per customer’s drawings, samples or requirements. To know more about Mechanical Seal call on +91-(2739) 271592 or email at info@leakpack.com.

Read More Articles:

What is the use of mechanical seals?

Why Mechanical Seal is Used in Pumps?

Inerested in your profile.